TRIALS OF A PROTOTYPE PLANT USING CLAY SLURRY TO REMOVE METALS FROM A MINE EFFLUENT

Dr P R J Smith, Aquatonics Ltd, Glenthorne, Searle Street, Crediton, Devon, EX17 2DB, UK. e-mail phil@aquatonics.com

SUMMARY

A Department of Trade and Industry (DTI) SMART award is being used to fund a 21 month study of the use of a dredged clay from Southampton Water (UK) to remove metals from effluents and polluted streams.

The first trials of a prototype treatment plant using clay slurry to remove metals were carried out at a disused tin mine called Wheal Jane, near Truro in Cornwall in late February/early March 2001. The main findings of the first trials are:

1. The prototype treatment plant worked well as a method of getting large volumes of effluent in contact with clay slurry, at a low cost and using relatively simple equipment.

2. Percentage removal rates could not be calculated for most metals, as they were below the analytical detection limits in the incoming effluent. Of the metals analysed only zinc and manganese concentrations were high enough to produce meaningful results.

3. Manganese was not removed by the prototype plant. This was not surprising as initial laboratory tests indicated that the glauconitic clay removed very little manganese.

4. Zinc was removed by the clays. The amount removed depended on the clay that was used. In several trials with "puddling clay" the amount of zinc removed ranged from 9% to 18%. A single trial with glauconitic clay at a slurry concentration of only 0.5% (dry weight) and a contact time of 21 minutes showed a much higher removal rate of 41%.

5. The results confirm that the glauconitic clay can remove zinc, even when the initial Zn concentration is low (1.7 ppm). This result compares favourably with a removal of 20-30% zinc in laboratory trials at a similar pH and slurry concentration, but with a contact time of 5 minutes and initial zinc concentration of 50 ppm.

6. Puddling clay is not suitable for further tests, which will use either glauconitic clay or other estuarine and marine clays.

INTRODUCTION

Laboratory trials using clay slurries to remove metals have been highly successful (Smith, 2000a & 2000b). The next stage in the programme was to try a prototype treatment plant at a disused mine site (Wheal Jane) in Cornwall. The advantages of this site were that large volumes of effluent were readily available, there was space for the plant and it was possible to discharge the clay and associated metals to a tailings lagoon. Until the clay slurry technology is completely proven it will be difficult to obtain permission from the Environment Agency to carry out large-scale trials on streams that have been affected by mine drainage.

A treatment plant for the mine water at Wheal Jane was installed by Hyder in autumn 2000. It was therefore not practicable to use actual mine water in the Aquatonics prototype. Instead the prototype was fed with effluent from a large tank (approximately 300,000 gallons or 1.35 million litres) that receives a variety of drainage from the site.

Two clays were used in the trials:

1. "Puddling clay" (used to line ponds and lakes etc) provided by WBB Clays, Newton Abbot.

2. A glauconitic intertidal clay from the upper reaches of Southampton Water (Eling Marshes). The intertidal clay from this site is likely to be very similar to the glauconitic sediment that will be dredged from Southampton Water if a proposed container terminal development gets planning permission. This clay has previously been used in laboratory tests (Smith, 2000a & 2000b)

THE PROTOTYPE PLANT

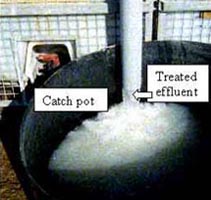

Photo 1. The Prototype Treatment Plant at Wheal Jane Photo 2. Treated Effluent and Clay

Emptying into Catch Pot for AnalysisThe prototype was designed and built by Western Aquaculture, a Devon company specialising in intensive aquaculture. The prototype was based on a design for tanks to treat aquaculture effluent at their fish farm, and uses compressed air and valves actuated by a timer to move water through the containers. The use of a compressor to move large volumes of water is much cheaper than using a pump. Precise details of the design cannot be given at this stage for reasons of commercial confidentiality.

The main components of the prototype are shown in Photos 1 & 2. Photo 1 shows the entire prototype. The black trough at the rear of the prototype distributed untreated effluent to each of the tanks (numbered 1-4 on Photo 1). Each tank had a capacity of 1 cubic metre and only filled if its valve is open. The tanks acted as mixing chambers and the contact time between the untreated effluent and the clay slurry could be adjusted with the timers on the valves. The tanks ran in pairs, with 1 & 3 filling whilst 2 & 4 were emptying. The process then reversed automatically. After some initial trials without clay the contact time was set to 21 minutes. This was about 4 times as long as the laboratory tests, but in the laboratory the solutions were completely stirred for the duration of each test. The volume treated by the prototype was 2 m3 in 21 minutes, or 1.59 l/second.

The structures above each tank allowed clay slurry to be added to individual tanks, and were also the discharge points for the treated effluent on the emptying cycle. The treated effluent from each of the tanks was discharged to a catch pot (Photo 2) to allow readings of dissolved oxygen, temperature, pH and conductivity to be taken using meters.

After the catch pot the effluent was gravity-fed through a plastic pipe into a nearby tailings lagoon that receives large iron-rich sludge from the Hyder treatment plant.

PROCEDURES

The trials took place from 28 February to 2nd March 2001 at Wheal Jane, near Truro in Cornwall. Permission for the trials was obtained from Carnon Enterprises, Hyder and the Environment Agency.

Effluent from a 300,000 gallon tank was used in the trials. A 4" pipeline from the 300,000 gallon tank ran along the main roadway at the Wheal Jane site. Near to the Aquatonics prototype there was a 4" valve on a T-junction, and this was reduced to 1.5" to obtain appropriate flows for the prototype. The untreated effluent was fed into the black trough on top of the prototype (See Photo 1).

Concentrated clay slurries were made up in advance of the trials. This clay concentrate was then added to the tanks (either directly or via the black trough). Dilution by the effluent reduced the clay concentrations to a maximum of 0.5% (dry weight) (see Figure 1). The first attempts at producing concentrated slurries were unsuccessful, and the clay concentrations in Runs 1A and 2A were far below those that were intended (0.012% & 0.031% respectively). Values close to the intended concentration of 0.5% (dry weight) were achieved in Runs 3A to 6A. A clay concentration of 0.5 % (dry weight) had previously been used in most of the laboratory experiments (Smith, 2000a & 2000b).

Effluent samples for suspended solids (SS) and metal analyses were taken a few minutes before the addition of the concentrated clay slurry. Meter readings of dissolved oxygen (DO); pH, conductivity and temperature were also obtained from the trough immediately before the start of each trial.

Meter readings of DO, pH, conductivity and temperature of the treated effluent were obtained from the catch pot soon after the tanks started to discharge. Samples of treated effluent for metals and SS analyses were taken when the emptying pair of tanks was approximately 50% discharged. These samples were taken just below the pipe (see Photo 2) before it reached the catch pot.

Samples were filtered using a 60 ml PlastipakÒ disposable syringe fitted with a MinisartÒ 0.2 m m filter, and the filtered solution was transferred to wide-mouth glass jars. Samples were not acidified. Analyses were usually completed within 24 hours.

All metal analyses were carried out on site by the Carnon Enterprises Laboratory, using atomic absorption spectrophotometry. Suspended solids were also analysed, using a filtration method for low concentrations and evaporation to dryness for the medium to high concentrations (up to 13% solids in the slurries before dilution).

Some build up of the puddling clay occurred in the trough and tanks during the trials. The trough and tanks were therefore thoroughly flushed out before the glauconitic clay was used.

RESULTS

The results from the meter readings obtained by Aquatonics and the laboratory results from Carnon Enterprises are summarised in Table 1. As results for copper, cadmium, nickel and iron were at or below their detection limits (Cu 0.01 ppm, Cd 0.001 ppm, Ni 0.1 ppm, Fe 0.1 ppm) they have not been included.

Table 1. Results from First Trials of the Prototype

RUN

CLAY TYPE

pH

Conductivity

(m S/cm)

DO

(% saturation)

DO

(mg/l)

Temperature (oC)

Suspended solids (mg/l)

Mn

(ppm)

Zn

(ppm)

Zn

(% removal)

1A In

Puddling

6.6

1530

114

NA

6.0

2.3

1.2

3.2

3

1A Out

6.7

1660

101

NA

6.0

115.3

1.2

3.1

2A In

Puddling

6.9

1220

113

12.8

5.5

10.2

0.9

2.3

9

2A Out

NA

NA

NA

NA

NA

311.1

0.9

2.1

3A In

Puddling

7.3

1270

97

10.6

7.2

7.1

0.6

1.7

12

3A Out

7.2

1200

96

10.7

6.3

3643.0

0.6

1.5

4A In

Puddling

6.7

1800

110

13.8

4.0

5.2

0.7

1.7

18

4A Out

6.5

1380

101

12.0

3.6

5132.7

0.7

1.4

5A In

Puddling

6.8

1380

103

11.7

4.5

5.5

0.7

1.7

18

5A Out

6.8

1300

102

11.7

4.4

4490.7

0.7

1.4

6A In

Glauconitic

6.9

1290

81

9.7

6.0

6.5

0.7

1.7

41

6A Out

6.6

1950

102

11.7

5.2

2445.2

0.7

1.0

DISCUSSION

The results for runs 3A – 5A in Table 1 show that the addition of the puddling clay at concentrations of 0.36 – 0.51% (dry weight) caused a reduction in the conductivity of the effluent. This situation was reversed with the estuarine glauconitic clay (run 6A) which has a high salt content and therefore caused an increase in the conductivity of the effluent. This could be a matter for concern if the treated effluent was discharged directly into a stream, as the conductivity would be above the norm for freshwater streams. There are many freshwater invertebrates that are found in coastal streams and ditches with similar conductivities, but they would not be considered typical components of an inland stream. If this proved to be an issue with field trials on polluted streams in Cornwall the main options would be to calculate the dilution available in the stream, or provide an initial washing step for the glauconitic clay.

Unfortunately several metals of interest (eg copper, cadmium and nickel) in the effluent feed were below the analytical detection limits and it was not possible to calculate the percentage removals for these metals.

The concentration of puddling clay had a clear effect on the amount of zinc removed (Figure 1). Due to the relatively small number of data points a trend line has not been fitted. It is likely that much higher concentrations of puddling clay would remove more than the 18% achieved in these trials. However, this would create a larger quantity of contaminated clay, and on balance it would be preferable to use glauconitic clay or similar in future trials.

In Run 6A the glauconitic clay from Southampton Water was used. The stock clay slurry had a concentration of 10.5% clay (dry weight) which should have produced a concentration in the treated effluent of 0.5% (dry weight). The clay content of the treated effluent was only 0.24%, suggesting that the sample taken was not typical. We have therefore assumed that clay concentration in this experiment was 0.5 % (dry weight). Run 6A produced the highest removal of zinc (41%) which was more than twice the amount removed by the same concentration of puddling clay (see Figure 1).

The percentage removal of zinc by glauconitic clay in Run 6A compares favourably with a removal of 20-30% zinc in laboratory trials at a similar pH and slurry concentration, but with a contact time of 5 minutes and a zinc concentration of 50 ppm (Smith, 2000a). As copper was removed much better than zinc in laboratory trials it suggests that the prototype plant will be able to remove high percentages of copper, probably in excess of 95%.

The first trials of the prototype at Wheal Jane have shown that production of a concentrated clay slurry and subsequent dilution of the slurry in the tanks is practical. We have also shown that over 40% of zinc is removed by the prototype (when the glauconitic clay was used), but that manganese is not removed by either of the clays that were tested. The latter is highly relevant, as one of the requirements of the main plant at Wheal Jane is to improve the removal of manganese.

FURTHER STUDIES AT WHEAL JANE

Aquatonics’ Prototype Plant

As laboratory tests always showed a higher removal for copper than zinc it is highly likely that the trials would have shown very good copper removal. Future trials will examine the ability of the prototype plant to remove copper. Permission will be sought (from the Environment Agency, Hyder and Carnon Enterprises) to artificially increase the copper concentration in the effluent feed so that accurate removal rates can be calculated. Until this permission is obtained no further trials of the prototype at Wheal Jane are planned.

Unipure Pilot Plant

An effluent treatment company called Unipure has a pilot plant at Wheal Jane, which could be adapted to include clay as part of the process. After discussions with Unipure we have obtained permission to carry out a week long trial of clay in the Unipure plant in mid April 2001.

ACKNOWLEDGEMENTS

Special thanks to:

Mark Yeoman of Western Aquaculture for construction and operation of the prototype plant.

Ken Barnes of Carnon Enterprises for providing facilities at Wheal Jane.

Clifford Rice of Carnon Enterprises for analysing all the samples.

Reg Proctor of WBB Clays for providing the puddling clay free of charge.

Hyder and the Environment Agency for allowing the trials to take place.

REFERENCES

Smith, P R J (2000a). The use of a glauconitic clay to remove metals from solution. Aquatonics Ltd, 9 October 2000.

Smith, P R J (2000b). Use of a glauconitic clay to remove copper from effluents produced during manufacture of printed circuit boards. Aquatonics Ltd, October 2000.

Dr Phil Smith, Aquatonics Ltd, 15 March 2001

| Terms & Conditions | Copyright Aquatonics Ltd | Site Map |